The Value of Vehicle Electrification

-

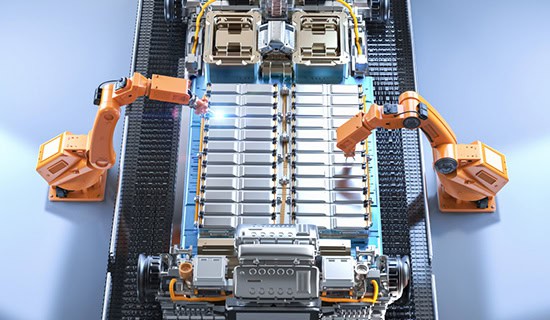

2025 Manufacturing Trends That Will Shape Electric Vehicle Success

Digital twins, advanced robotics, AI-driven quality control, and sustainable practices will be used in 2025 to address the challenges EV manufacturers face.

Read more -

How Automakers Can Accelerate Their Transition to EVs

A discussion about electric vehicle design and production challenges and how automakers can leverage Digital Twins, simulations, and more to help.

Read more -

How Augmented Reality is Shaping EV Development and Design

From prototyping and design to workforce training and sustainable production, augmented reality is making an impact on the way vehicles are developed and brought to market.

Read more

Trending Now

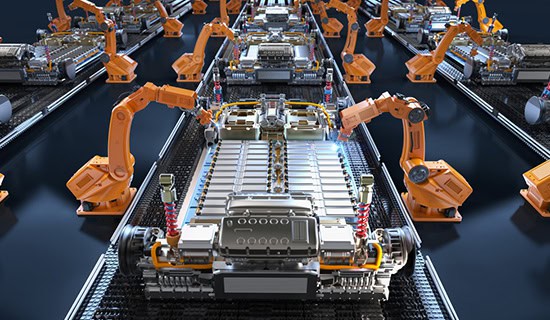

Vehicle Electrification: End-to-end production management

Through the rapid expansion of the EV market, manufacturers need to meet critical production goals to succeed. In this eBook learn how end-to-end production management empowers manufacturers to plan, validate, and optimize manufacturing processes.

Digital Technologies Key to Meeting EV Market Expectations

EV automakers need great design, development, and manufacturing flexibility afforded by digital technologies to meet ever-changing and stringent customer expectations.

Use Cases

Digital Technologies Key to Meeting EV Market Expectations

EV automakers need great design, development, and manufacturing flexibility afforded by digital technologies to meet ever-changing and stringent customer expectations.

What Will It Take to Achieve EV Zero Waste?

The path to zero waste in EV manufacturing is filled with challenges. By embracing new technologies and practices, the EV industry can move closer to a future where production processes are efficient, cost-effective, and truly sustainable.

Navigating Regulatory Mandates and the Path to a Greener Future

By adopting an integrated approach that addresses every stage of the production process, manufacturers can comply with regulations and lead the charge toward a more sustainable future.

From Best Practices to Zero Waste: Transforming EV Manufacturing Sustainability

Explore how the EV industry is evolving towards sustainability by building on best practices, reducing waste, and embracing circular economy principles.

Driving Change: The Impact of Emerging Technologies on Electric Vehicle Production

A variety of emerging technologies will play a major role in electric vehicle (EV) design and production. Here are some of the major ones to be aware of.

A High-level Look at How EVs Impact Auto Manufacturing

Automakers are turning to digital twins and other technologies to overcome the complexities of electric vehicle (EV) design and manufacturing.

Electrify the future of automotive with Siemens Vehicle Electrification

Be introduced to how automotive manufacturers can accelerate EV innovation and flawlessly launch vehicles onto the market with Siemens Vehicle Electrification solutions.

Drive vehicle electrification and manage increasing complexity by transforming electric vehicle development

Download the eBook to learn how Siemens is helping OEMs develop the next generation of safe and reliable electric vehicles with a mass-market appeal to drive change for mobility.

Imperatives as Automotive Industry Pivots to Vehicle Electrification

As the automotive industry pivots towards vehicle electrification, explore 5 key takeaways to accelerate electric vehicle development.

Accelerate EV development with a collaborative virtual environment

The explosive growth of the EV market demands an agile and collaborative manufacturing approach. Learn how a unified, collaborative virtual environment can help.

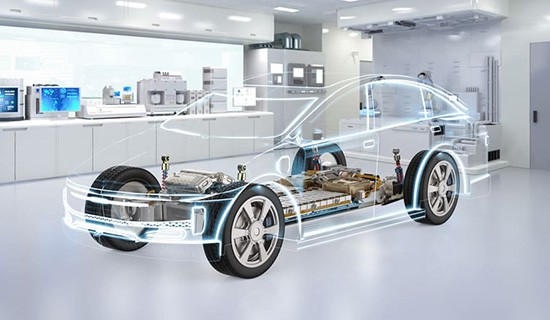

The comprehensive virtual engineering solution for EV development

To meet the market’s growing EV demands, automakers need to be able to design, develop, and produce EVs quickly and efficiently.

How Augmented Reality is Shaping EV Development and Design

From prototyping and design to workforce training and sustainable production, augmented reality is making an impact on the way vehicles are developed and brought to market.

Balancing Speed and Quality in Compressed Automotive Timelines

In an industry where development timelines are increasingly compressed, automakers face a critical choice: prioritize speed or maintain quality.

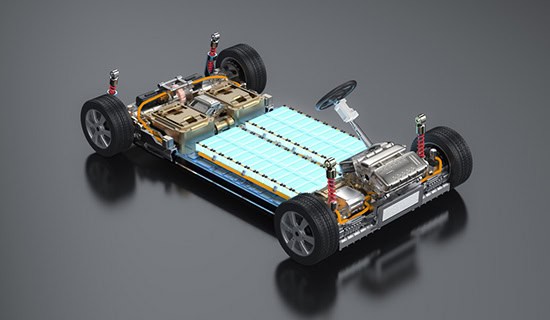

Rapid Advancements in EV Battery Technology: What Automakers Need to Know

To integrate changes in battery technology into their electric vehicles, automakers need great design and development flexibility, such as that afforded by the use of digital twins, virtual commissioning, and more.

Enhancing Digital Twins with Digital Engineering Capabilities

By integrating digital engineering methodologies with digital twins, EV manufacturers can streamline operations, enhance collaboration, and maintain a competitive edge in the increasingly complex and dynamic EV marketplace.

Using Simulations and Digital Twin Technology to Address Electric Drive Design and Engineering Challenges

Compared to its counterpart in an internal combustion engine vehicle, predicting motor electromagnetics, noise, heat transfer, stresses, or simulating specific phenomena on an electric drive requires new fields of expertise and mindsets.

Comprehensive Design and Optimization Simulation Accelerates EV Engineering

Explore the power of Comprehensive Design and Optimization Simulation (CDOS) to transform electric vehicle engineering. From concept to mass production, CDOS enables simulation across all engineering disciplines.

Accelerate EV development with comprehensive design and simulation

Learn how your business can reduce the need for expensive physical prototypes and testing, minimize cost and accelerate time to market.

Using simulation to design a working, all-electric Le Mans race car to promote sustainability

Discover how Siemens Xcelerator helped InMotion create a solid engineering foundation to succeed in the e-racing ecosystem.

EV Powertrain Design Complexity Needs Digital Twin Technology

By using digital twins, automakers can enhance the precision, efficiency, and speed of EV powertrain development, leading to better-performing, more reliable, and cost-effective electric vehicles.

EV Manufacturers Double Up on Digital Twins

Both the design of an EV and its production require new thinking, new technology, and new processes. EV automakers are turning to digital twins for help.

2025 Manufacturing Trends That Will Shape Electric Vehicle Success

Digital twins, advanced robotics, AI-driven quality control, and sustainable practices will be used in 2025 to address the challenges EV manufacturers face.

How Automakers Can Accelerate Their Transition to EVs

A discussion about electric vehicle design and production challenges and how automakers can leverage Digital Twins, simulations, and more to help.

Overcoming Thermal Management Challenges in Electric Vehicles with Advanced Design Technologies

The shift towards hybrid-electric and fully electric vehicles brings new thermal management challenges. Automakers are turning to advanced design technologies, such as digital twins, simulations, and virtual prototyping, to address these challenges.

Essential Technologies for Automakers to Ride Out EV Market Variability

Virtual prototyping, virtual commissioning, and digital twin technologies provide EV makers with the agility to navigate regulatory changes, economic fluctuations, and changing customer preferences, ensuring they remain competitive in today’s dynamic market.

Vehicle Electrification: End-to-end production management

Through the rapid expansion of the EV market, manufacturers need to meet critical production goals to succeed. In this eBook learn how end-to-end production management empowers manufacturers to plan, validate, and optimize manufacturing processes.

How Digital Twins and Real Time Data Accelerates Time to Value

Digital twins and real-time insights reduce time to value, enhance product quality, and help EV manufacturers maintain a competitive edge in what often seems like a frustratingly volatile market.

EV Makers Need Modern Design and Manufacturing Practices

The pressure on EV makers to bring more models with more complex technology to market faster requires increasingly sophisticated design software, digital twin technology, and modern manufacturing practices.

EV Automakers Must Prepare for the Technology Arms Race

Technology is the new differentiator with EVs. Companies are no longer competing on the driving range. Here’s what you need to know.

Smart Manufacturing Essential for the Transition to EVs

Widespread adoption of EVs is hampered by challenges related to affordability, batteries, and the supply chain for electrical components. Smart manufacturing may be able to help automakers address each of these areas.

Resources

Enhancing Digital Twins with Digital Engineering Capabilities

By integrating digital engineering methodologies with digital twins, EV manufacturers can streamline operations, enhance collaboration, and maintain a competitive edge in the increasingly complex and dynamic EV marketplace.

What Will It Take to Achieve EV Zero Waste?

The path to zero waste in EV manufacturing is filled with challenges. By embracing new technologies and practices, the EV industry can move closer to a future where production processes are efficient, cost-effective, and truly sustainable.

Comprehensive Design and Optimization Simulation Accelerates EV Engineering

Explore the power of Comprehensive Design and Optimization Simulation (CDOS) to transform electric vehicle engineering. From concept to mass production, CDOS enables simulation across all engineering disciplines.

Accelerate EV development with comprehensive design and simulation

Learn how your business can reduce the need for expensive physical prototypes and testing, minimize cost and accelerate time to market.

Using simulation to design a working, all-electric Le Mans race car to promote sustainability

Discover how Siemens Xcelerator helped InMotion create a solid engineering foundation to succeed in the e-racing ecosystem.

From Best Practices to Zero Waste: Transforming EV Manufacturing Sustainability

Explore how the EV industry is evolving towards sustainability by building on best practices, reducing waste, and embracing circular economy principles.

How Digital Twins and Real Time Data Accelerates Time to Value

Digital twins and real-time insights reduce time to value, enhance product quality, and help EV manufacturers maintain a competitive edge in what often seems like a frustratingly volatile market.

EV Powertrain Design Complexity Needs Digital Twin Technology

By using digital twins, automakers can enhance the precision, efficiency, and speed of EV powertrain development, leading to better-performing, more reliable, and cost-effective electric vehicles.

Accelerate EV development with a collaborative virtual environment

The explosive growth of the EV market demands an agile and collaborative manufacturing approach. Learn how a unified, collaborative virtual environment can help.

The comprehensive virtual engineering solution for EV development

To meet the market’s growing EV demands, automakers need to be able to design, develop, and produce EVs quickly and efficiently.

Driving Change: The Impact of Emerging Technologies on Electric Vehicle Production

A variety of emerging technologies will play a major role in electric vehicle (EV) design and production. Here are some of the major ones to be aware of.

EV Makers Need Modern Design and Manufacturing Practices

The pressure on EV makers to bring more models with more complex technology to market faster requires increasingly sophisticated design software, digital twin technology, and modern manufacturing practices.

A High-level Look at How EVs Impact Auto Manufacturing

Automakers are turning to digital twins and other technologies to overcome the complexities of electric vehicle (EV) design and manufacturing.

EV Manufacturers Double Up on Digital Twins

Both the design of an EV and its production require new thinking, new technology, and new processes. EV automakers are turning to digital twins for help.

Electrify the future of automotive with Siemens Vehicle Electrification

Be introduced to how automotive manufacturers can accelerate EV innovation and flawlessly launch vehicles onto the market with Siemens Vehicle Electrification solutions.

Drive vehicle electrification and manage increasing complexity by transforming electric vehicle development

Download the eBook to learn how Siemens is helping OEMs develop the next generation of safe and reliable electric vehicles with a mass-market appeal to drive change for mobility.

Imperatives as Automotive Industry Pivots to Vehicle Electrification

As the automotive industry pivots towards vehicle electrification, explore 5 key takeaways to accelerate electric vehicle development.

EV Automakers Must Prepare for the Technology Arms Race

Technology is the new differentiator with EVs. Companies are no longer competing on the driving range. Here’s what you need to know.

Smart Manufacturing Essential for the Transition to EVs

Widespread adoption of EVs is hampered by challenges related to affordability, batteries, and the supply chain for electrical components. Smart manufacturing may be able to help automakers address each of these areas.

Transforming Production to Meet Variable EV Demand

Many technologies, including digital twins, virtualization, and more, can help auto manufacturers transition to EVs and meet changing EV production requirements.