Recharge Your Electric Vehicle Development

Compared with Internal Combustion Engine (ICE) vehicles, hybrid-electric and electric vehicles (EVs) require a significant increase in electronic components, a more complex electrical architecture, and more. Design requires engineering collaboration across domains. Increasingly, digital twins are providing the needed platform for that collaboration.

EVs by the Numbers

85 million

There will be 85 million EVs on the road by the end of 2025

(Source: Gartner)

50% lower

EV battery prices are expected to fall by almost 50% by the end of 2026

(Source: Goldman Sachs)

40% to 70%

Lifestyle changes, including the use of EVs, can cut greenhouse gas emissions by 40% to 70% by 2050

(Source: IPCC)

62% to 86%

Automakers will face a global talent shortage of 2.3 million skilled workers by 2025

(Source: Wizehire)

Top Challenges in Bringing EVs to Market

Design Complexity

- Battery technology is rapidly evolving

- Cross-domain collaboration required

- Customer preferences change quickly

Development Obstacles

- Quality issues with compressed timelines

- Frequent production line changes

- Thermal management

How a Digital Twin Helps

Vehicle Design and Optimization

- Replicate physical properties

- Simulate real-world conditions

- Test different scenarios

Benefits

- Faster design iterations

- Reduced costs

- Easier to innovate

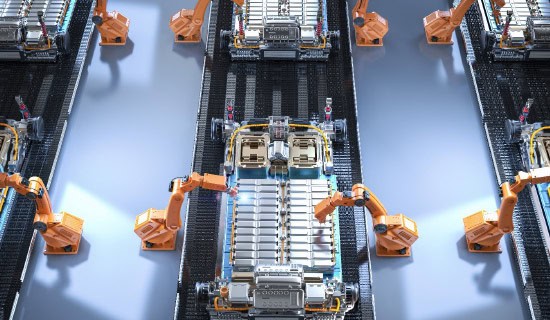

Manufacturing Process Optimization

- Test assembly line workflows

- Simulate manufacturing processes

- Identify bottlenecks

Benefits

- Efficient production processes

- Lower production costs

- Reduced downtime

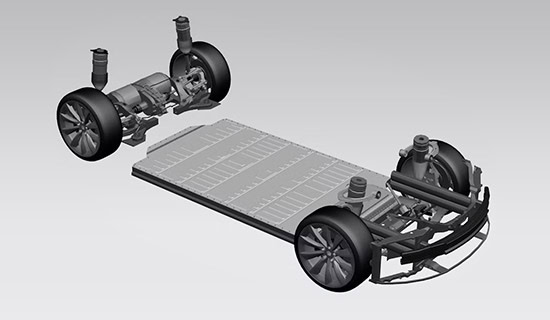

Battery Development and Management

- Optimize battery life

- Simulate battery performance under different conditions

- Monitor battery health

Benefits

- Improved battery performance

- Extended battery life

- Enhanced safety

How Siemens Helps

Automakers that add hybrid-electric and electric vehicles to their automotive mix open up streams of new long-term revenue, meet customer demands for environmentally sound cars, and help reduce global greenhouse emissions. Siemens helps get those vehicles to market faster via a comprehensive suite of solutions to support the use of digital twins in the design, development, and production of electric vehicles (EVs). Its offerings are part of the broader Siemens Xcelerator portfolio, which integrates software, hardware, and services to enable digital transformation in industries, including automotive.

Resources

Learn how forward-looking manufacturers are achieving digital continuity between innovative product designs and best-in-class performance in this eBook.

Download now

By leveraging comprehensive digital twins of the product and production lines, manufacturers can design and validate assembly processes and entire facilities virtually, improving quality and accelerating production ramp-up.

Download now

Unleash efficiency, reduce costs, and accelerate production with digital twin technology.

Download now