As a result, automotive manufacturers find they must constantly innovate to reduce costs, improve quality, and deliver value to customers (better fuel economy, advanced features, features-as-a-service, etc.). On the operational side, they also need to build multiple vehicle configurations on the same line to support customization and EV manufacturing along with traditional vehicles.

Increasingly, the path to addressing all of these issues is to transition to a smart automotive manufacturing strategy. Elements should include rapid factory transformation, virtual manufacturing engineering, and intelligent production excellence.

In particular, there is a need for virtual commissioning, which refers to the use of digital simulation models to replicate and test manufacturing processes, machines, work cells, production lines, or entire factories before implementing them in the real world. The technique allows manufacturers to rapidly transform factories and operations. Specifically, it allows a manufacturer to validate and optimize the design and functioning of a manufacturing system without the need for physical prototypes or actual production facilities.

Additionally, such an approach helps Identify issues virtually, avoiding the costly “design, build, test, break” iteration cycle that delays product launches and shuts down working production lines.

Furthermore, embracing the wide range of technologies that make manufacturing smart requires the right equipment, industry knowledge, technical expertise, and more. The best way to approach the adoption of smart manufacturing is to establish intelligent manufacturing excellence. That typically includes:

- Moving to an environment with connected production lines.

- Making use of edge devices to collect data from every line.

- Migrating to a cloud environment, making use of data lakes to convert data into valuable insights into performance, energy use, raw material consumption, and more.

- Employing prescriptive insights to optimize line performance, do predictive maintenance, and eventually have the line manage itself.

Factors driving the need for smart automotive manufacturing

The automotive industry is in transition. For years, automotive manufacturers have had to meet ever-more stringent global regulations on fuel economy and emissions. That still remains the case. But now, there is growing pressure to make the move to EVs. Additionally, the cars themselves are becoming much more complex electronically to support new software-defined features and provide differentiation with competitors and among cars in the same model line.

Furthermore, in today’s market, there is a need to support much higher levels of personalization or customization due to fast-changing consumer/market demands. This requires more flexibility in manufacturing to make multiple configurations on the same line. Increasingly, manufacturers are turning to digital twins of work cells, production lines, and entire factories combined with virtual commissioning to support rapid factory transformation. That allows a manufacturer to change production processes and outputs more quickly to match changing consumer preferences and regulatory mandates.

Smart manufacturing can help these areas. However, to show how, it makes sense to look at the issues in a bit more detail to appreciate where and why smart automotive manufacturing is needed.

Perhaps the biggest reason smart manufacturing is needed is the inter-dependencies of modern automotive production. Every advance potentially introduces new issues.

For example, over the years, automotive manufacturers have improved the aerodynamic design of their vehicles. This not only helped improve fuel economy but also reduced wind noise from entering car cabins, especially at high speeds.

This does not seem like it would be a problem, but it is. Eliminating a white noise like the sound of wind rushing by the car uncovers other low-decibel noises that were previously masked, such as the clatter of an engine. As a result, manufacturers had to increase the use of sound-deadening materials like foam, rubber seals, paint sealers, and insulating spray foam in every nook and cranny of their vehicles.

Similarly, manufacturers are making use of new composite materials for structural elements to lighten an auto’s weight (and thus helping to improve fuel economy). A manufacturer might use a smaller engine that runs at higher speeds to save weight. The issue here is that engine temperatures can be much higher than before.

The impact: traditional lubricants used when a car is all-metal construction or engines run at lower speeds do not perform well or break down. As a result, many had to find new lubricants that worked equally well at higher temperatures or when different elements made of different materials (metal and composite) came together.

The main issue is that everything is interrelated. A slight change in a manufacturing process can have unforeseen implications. Traditional manufacturing processes often meant that a manufacturer did not discover an issue due to a process change until after the vehicle was assembled or in the field.

Smart manufacturing has the potential to address these and many other issues before a single car has been built.

Supply chain issues continue to dominate

Supply chain problems permeated the global economy after the pandemic. All types of parts and components were in short supply or took extraordinarily long times to arrive. The automotive manufacturing industry was highly impacted, like many other industries.

While many of the pandemic-related supply chain issues have been resolved, there are other factors impacting the availability of critical components. One area of particular interest is chip supply in light of global unrest. Specifically, there is an ongoing trade dispute between the United States and China, with each country imposing or threatening to impose large tariffs or prohibiting microchip companies from doing business in one country or the other.

Why does this matter? It is estimated that the average modern car has between 1,400 and 1,500 semiconductor chips. And some cars can have as many as 3,000 chips. They are used in emissions systems, advanced driver assistance systems, and engine control units.

How much of an impact did this have on manufacturers? In 2021, the automotive industry lost more than $200 billion due to chip shortages. Eleven million fewer vehicles were produced. Manufacturing plants sat idle. Ford suspended operations at some plants to focus efforts on truck assembly, where the margins are better, according to an article by MIT Management, Sloan School.

In 2022, many automakers decided to ship some of their most popular models without all the chips they were designed to include. For example, Automotive News reported that “Ford told its dealers it would start building Explorers, its best-selling SUV in the U.S., without the computer chips that enable rear-seat climate control, meaning that backseat passengers won’t be able to adjust the air conditioner and heat.” The company said it would install the missing chips once they become available.

The transition to EVs has also resulted in supply chain challenges that require manufacturers to work with suppliers and vendors outside their previous supply chains.

The important point here is that supply chain management has radically changed over the last year due to the changing nature of cars. In the past, supply chain operations only needed to be concerned with raw materials and traditional automotive parts and components. Now, they must deal with the supply of chips, lithium-ion batteries, composite materials, and more.

Software is software

Modern cars offer many sophisticated features and functions, all of which are delivered via software. That includes advanced driver assistance systems, software-defined engine performance and handling, emission control systems, infotainment systems, and more.

Increasingly, software is an important part of modern cars, often enabling advanced features and differentiating OEMs offers from one another. When there is a problem, it can stop production. That was the case in early 2023. According to the Ford Authority, “Production of the 2023 Ford Escape and 2023 Lincoln Corsair was on hold for several weeks due to a software bug impacting pre-production versions of both crossovers.”

So, automotive manufacturers are now in the software business. And like any software vendor, they must make software development, quality assurance, installation, and testing part of any end-to-end production process.

How smart automotive manufacturing helps

Every aspect of the auto manufacturing business environment and the economics that drives it, from raw materials to supply-and-demand to customer service and partnerships, is changing.

Fortunately, many new technologies that can help are reaching a level of maturity to deal with these issues. Auto manufacturing is seeing increased use of smart sensors and industrial internet of things (IIoT) devices. Plants now have ubiquitous connectivity, allowing the data from such devices to be collected, shared, and analyzed easily. Such data from legacy OT systems is increasingly being combined with enterprise IT data like that found in ERP and CRM systems.

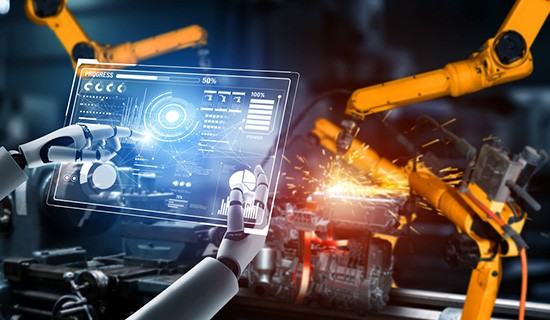

Many are applying advanced analytics (predictive analytics) to that collective data to spot issues in the making, improve maintenance efficiency, reduce downtime, and optimize supplies. More advanced organizations are making use of virtualization technologies and digital twins that allow for the melding of digital and physical worlds. A manufacturer bringing these technologies and elements together can realize many benefits.

Enter the world of smart manufacturing, which lets an auto manufacturer plan, optimize, and test operations virtually before physically commissioning anything.

Using a digital twin, a smart manufacturer can develop and try out work cells, manufacturing lines, and even an entire plant virtually. The data from this digital representation can be used to virtually identify obstacles, test solutions, and validate new scenarios.

Virtualizing operations using digital twins lets manufacturers design new production lines that are highly optimized from scratch. With virtual development, a manufacturer can practice the launch of a new product to ensure that costly last-minute changes do not delay a launch. Virtual manufacturing development allows a company to optimize production processes, pre- and post-launch; practice a product launch with virtual commissioning; share product design data with manufacturing early in the development cycle; and easily duplicate or relocate manufacturing lines anywhere in the world. Using such an approach, one company was able to realize a 30% reduction in development time and a 200% gain in productivity.

One issue that comes up when talking about smart manufacturing and virtual operations is how to bring legacy plants, production lines, and systems into the mix. Obviously, not every manufacturing line can be built from the ground up, which makes it challenging to implement cutting-edge technologies as they become available.

A smart manufacturing solution should provide a way for a manufacturer to update legacy equipment with sensors and edge devices to collect and analyze data for trends and prescriptive insights. Technologies like artificial intelligence (AI) and IIoT can connect work cells, assembly lines, and the entire plant to optimize production processes and resolve real-time issues.

Once legacy systems are brought into the fold, a manufacturer can make use of continuous communication loops that take insights from the generated data to take action. Such a feedback loop can be used to create manufacturing lines that can manage themselves to prevent errors, minimize downtime, and produce quality parts at launch and throughout the product lifecycle. A virtual environment like this offers the flexibility to quickly fine-tune and adjust production to match changing customer demands.

Feeding the data back into a digital twin of the product and manufacturing operations also improves the quality of future production. For example, a manufacturer might set up a feedback loop between insights collected from the field and product engineering to make improvements based on the drivers’ behavior.

Poised for a rapidly changing market

Companies in the automotive industry are pushing to develop the next generation of autonomous, electric, connected, and shared vehicles, which are becoming more and more software-defined. As noted above, they are thus facing new design challenges.

When trying to embrace changing consumer demands, supply chain disruptions can cause material and component shortages, leading to unexpected downtime. There are also ongoing labor shortages, especially in some of the new technology areas.

Many manufacturers do not have an infrastructure in place to help. They rely on employees to manually pull together data that could help, or they use some mix of manual processes plus software. A smart manufacturing approach can help a company quickly evolve to adopt and implement more intelligent factory capabilities that meet the needs of today and address the challenges of tomorrow. Virtual technologies and digital twins can reduce the time to launch, improve quality, decrease warranty costs, eliminate recalls, and increase throughput to maximize efficiency.

Sustainability takes center stage

Manufacturers are increasingly leveraging smart technologies to enhance their sustainability efforts across various aspects of production and operations. Some essential ways smart technologies are being used include:

Energy Management: Smart technologies enable better energy management by using sensors and IoT devices to monitor and optimize energy usage. This can include automating lighting, heating, and cooling systems based on real-time occupancy and environmental conditions, as well as integrating renewable energy sources more efficiently.

Resource Efficiency: Advanced analytics and AI help in predicting maintenance needs and optimizing resource use, reducing waste and extending the lifespan of machinery. For example, predictive maintenance can foresee equipment failures before they occur, minimizing downtime and conserving resources that would otherwise be used for repairs.

Supply Chain Optimization: Smart technologies enhance supply chain transparency and efficiency by providing real-time data on material flows, inventory levels, and logistic needs. This reduces waste, improves delivery times, and lowers carbon emissions associated with transportation.

Waste Management: Automated sorting and recycling processes powered by smart technology can help separate and reuse materials more efficiently. AI-driven systems can also identify and categorize waste types for better recycling outcomes.

Water Management: IoT sensors can monitor water usage and detect leaks in industrial processes, helping to conserve water, which is particularly crucial in water-scarce regions.

By embedding these smart technologies into their operations, manufacturers not only improve their sustainability but also often see benefits in terms of reduced costs and enhanced compliance with environmental regulations.

Expanding in the scope of smart automotive manufacturing

Modernizing manufacturing processes by connecting the data of all engineering disciplines to the knowledge of the shop floor is essential. It allows a manufacturer to monitor performance and predict operational issues in real time. By using sensors, smart devices, and IIoT technology, a plant will have a complete loop of manufacturing communication.

Additionally, manufacturers are increasingly using advanced automation to improve operations. One area ripe for automation is process automation. That is where software and AI-driven systems automate many back-office and production-related processes, from order entry and procurement to inventory management. This kind of automation helps streamline operations and reduce the likelihood of errors.

Many also use the data collected on production lines to automate decisions about production scheduling, control systems, and supply chain logistics.

The bottom line: A smart manufacturing solution helps automotive manufacturers in many ways. It can help boost flexibility and allow a manufacturer to react faster to issues on the line. That can be accomplished by deploying edge technology that incorporates automation and self-correcting capabilities. It also reduces energy use and carbon footprint by leveraging advanced scheduling technologies.

Optimize automotive manufacturing processes with Siemens simulation software. [geoip_detect2_show_if country=”AX,AL,DZ,AD,AO,AM,AT,AZ,BH,BY,BE,BJ,BA,BW,BG,BI,CV,CM,CF,TD,KM,CG,CI,HR,CY,CZ,DK,DJ,EG,ER,EE,SZ,ET,FO,FI,FR,GA,GM,GE,DE,GH,GI,GR,GG,GN,VA,HU,IS,IR,IQ,IE,IM,IL,IT,JE,JO,KZ,KE,KW,LV,LB,LS,LR,LY,LI,LT,LU,MG,MW,ML,MT,MR,MU,YT,MD,MC,ME,MA,MZ,NA,NL,NE,MK,NO,OM,PL,PT,QA,RE,RU,RW,SH,SM,ST,SA,SN,RS,SC,SL,SK,SI,ZA,ES,SD,SE,CH,SY,TZ,TG,TN,TR,UG,UA,AE,GB,EH,YE,ZM,ZW”][else][/geoip_detect2_show_if]Sign up for a free trial.