Learning to manage increasingly complex systems and avoid disruptions is only possible with clear visibility on every piece of the business.

Conditions are changing faster than ever for global energy distribution providers. Utilities, in particular, must maintain reliability, avoid disruptions, improve resiliency, integrate renewable generation, enhance customer options and services, and ensure sound financial performance—all simultaneously.

Yet energy companies are now empowered with data on every aspect of their facility—from embedded sensors and intelligence devices, information on the composition of a circuit breaker’s insulation to unstructured video footage of transmission lines, all the way to the safety and productivity of their workforce.

All of this data provides a unique opportunity, but only for those who know how to leverage it. If used correctly, energy companies could more easily meet the power needs of customers all while ensuring worker safety and profitability – but this is easier said than done.

As energy sources continue to change, having clear insights from both online and offline data—starting at the substation and going all the way to the cloud—is difficult without the right set of tools. This is especially true if energy companies want to stay ahead of potentially catastrophic situations, whether it’s a natural disaster or an unexpected asset malfunction. Data insights are particularly powerful in helping to maintain assets performing at the most productive level possible and in helping to manage and balance the entire grid.

See also: Energy and Utilities Fighting Disruptions with Data

Growing complexity

Global reliance on electric power continues to grow, making outages more disruptive and expensive than ever before. Meanwhile, substations and other power grid assets are aging beyond their design lifecycle, and utilities are seeking a better balance between maintenance, life extension, and replacement.

The health of assets is closely tied to the core utility values of safety and reliability, and in order to stay ahead, grid operators need to make sound decisions on maintenance and replacement while maximizing the efficiency of their grids. This is amplified by the needs of older infrastructure, which requires more frequent in-person maintenance, inspections, and servicing that can be costly, labor-intensive, and sometimes hazardous.

While automation has improved over time, the inability of some generators to interconnect with the larger grid requires manual intervention, often initiated by phone calls from the grid operator to larger generators. This means that maintaining grid assets is often a dynamic, human-reliant challenge, which has significant financial, legal, and safety implications. This is especially true in the utility industry, where maintenance is often tightly integrated into operations and on the potential consumer impact. Managing outages due to weather or equipment failure requires situational awareness and careful coordination of many factors, including line isolation, power flows, maintenance, and the real-time management of all employees from linemen to the service personnel dispatched to restore power.

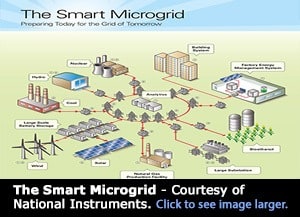

Amid all these growing challenges, what does the path forward look like? How this complexity is managed requires an understanding and view into the multiple levels of the grid, each with its own set of technologies. For example, at the field level, a number of communications interconnect through a wide range of equipment such as RTUs, merging units, and transformers. Without a view of each level, timely information is missed, resulting in costly disruptions that can create a negative ripple effect across the entire operation. Managing the health of critical assets will only become more important going forward as digitization occurs across the energy industry.

Preventing outages one data point at a time

The grid must balance supply and demand precisely at all times. As loads change, generation must respond to match, keeping voltage and frequency steady. Utilities can address these fast-changing shifts by leveraging prognostics data, system data, workforce data, and even data on energy pricing.

While today’s grid controls use a variety of techniques to balance supply and demand to keep electric grids stable, utilities can use data analytics and asset performance management to improve grid reliability. It’s only in the last few years, as technology has evolved, that we could digitalize the data in these traditionally analog assets. Solutions that are digital in nature and that leverage wired and wireless communication networks to provide visibility and seamless access from the control room to mobile devices, such as supervisory control and data acquisition (SCADA) and RTUs, is also key.

Currently, grid operators continuously monitor the loads on various transmission and distribution lines to ensure a high level of operational flexibility in case of unexpected failures or load changes. However, digitalization of substations, harnessing the power of asset performance management (APM), has enabled operators to move away from time-based, routine maintenance and guessing how to maximize energy in their power system.

By leveraging the real-time nature of SCADA solutions and the integration of controls at the data center through communications, utilities can easily and safely control and monitor assets remotely, allowing for newfound flexibility. This helps utilities support their workforce and make the best use of their time. With a robust data plan and digitized hardware, utilities no longer need to send a team out for routine maintenance on a power line 100 miles away. Or the team doesn’t have to guess at the power quality in the power system. Instead, the SCADA system, in conjunction with IEDs and RTUs, monitors harmonic distortions, voltage drops, and more, ensuring mission-critical infrastructure operations continue. Automation and data enable operators to maximize the system’s power.

Visibility to prevent disruptions

By harnessing digital data generated by devices and sensors, asset owners and operators gain a full and transparent overview of their entire operation. Data can bring to life a new understanding of how everything is interrelated and interdependent.

For example, data can give operators a heads up on when an asset will fail, based on past performance of the asset as well as other assets in the energy supply chain. It can then help guide operators on how to reroute the power flow to minimize disruptions, maximizing power transmission, and more.

Looking toward the future, energy companies will continue to experience unprecedented change alongside rapidly evolving consumer expectations, system interdependencies, and changing power flows.

For those that want to stay ahead, learning to manage increasingly complex systems is only possible with clear visibility on every piece of the business. Data analytics, SCADA solutions, asset performance management tools, and a mission-critical communication network can help avoid disruptions by providing clarity where it currently does not exist.