Private 5G networks offer the data speeds, reliability, low latency, and more for pervasive device connectivity to enable innovative data-driven manufacturing applications.

Why 5G in Manufacturing?

Industrial Ethernet is the backbone of operational infrastructure in many manufacturing settings. Typically running at data speeds of up to 100 megabits per second (Mbps), Industrial Ethernet networks implement protocols to provide determinism and real-time control.

When it is cost-prohibitive or infeasible to install wired Ethernet networks, Wi-Fi and 3G/4G wireless technologies are often the next best alternative. These “hard-to-wire” use cases include autonomous mobile robots (AMRs), trucking fleets, and industrial plants that have a large geographic coverage area.

With Industry 4.0, the use of operational data is fundamentally changing in that the massive amount of sensor data generated from edge devices will be gathered, stored, and processed with artificial intelligence (AI) in real-time on the industrial premise, commonly referred to as the Industrial Edge. Private 5G networks have the potential to be a key enabler in this distributed compute paradigm, particularly with devices generating video data. This is because 5G offers data speeds up to 20 gigabits per second (Gbps) and the possibility of improved security, data rates, latency, device density, reliability, and determinism compared to 4G.

Wireless technologies, including 5G, also increase manufacturer agility by giving them greater flexibility to quickly install new network connections. As manufacturers see the need for faster and more flexible networks in factories, they may decide to replace some or all of their legacy Industrial Ethernet networks with 5G networks down the road.

5G Use Cases in Industrial Environments

Many remote and mobile devices, such as cameras, actuators, robots, machines, display screens, and other systems, require fast and reliable connectivity. In greenfield deployments, 5G could supersede wired networks by supporting lower deployment costs over a wider coverage area, and greater mobility and flexibility. Here are some examples in which 5G can improve operational processes in industrial environments.

Automated guided vehicles (AVGs): Faster routes, and fewer traffic jams and collisions

- Transition from AVGs moving along pre-defined lanes to AI and M2M communications helping optimize paths and avoid collisions.

Part and product picking: More efficient and accurate part picking in warehouses and fulfillment centers

- Transition from requiring parts to be in fixed locations and orientations to detecting parts in various positions and locations using AI-based vision systems.

Monitoring of workers in hazardous areas: Improved safety and crisis avoidance

- Transition from a lack of electronic monitoring of restricted or unsafe areas to AI-based vision systems alerting workers when they deviate from safety protocols or danger is imminent.

Equipment repair: Faster and lower cost equipment repair through remote collaboration

- Transition from repair assistance lacking visual support (necessitating on-site specialized technicians) to augmented reality enabling off-site specialists to help non-expert technicians.

5G Is Designed With The Capability to Support Manufacturing

- Security built into the 5G spec: Private 5G networks

- Ultra-high-definition streaming: Data rates as high as 20 Gbps

- Real-time control:Latency of 1 millisecond or lower

- Support more controllers and sensors: High density from advanced antenna technology

- Fewer points of failure: Device-to-device communication redundancy

- Greater determinism and data privacy: 5G network split into multiple virtual networks

5G will enable technical upgrades to stringent performance targets that previously could only be addressed with hardwired networks.

5G Private Networks Enhance Security and Determinism

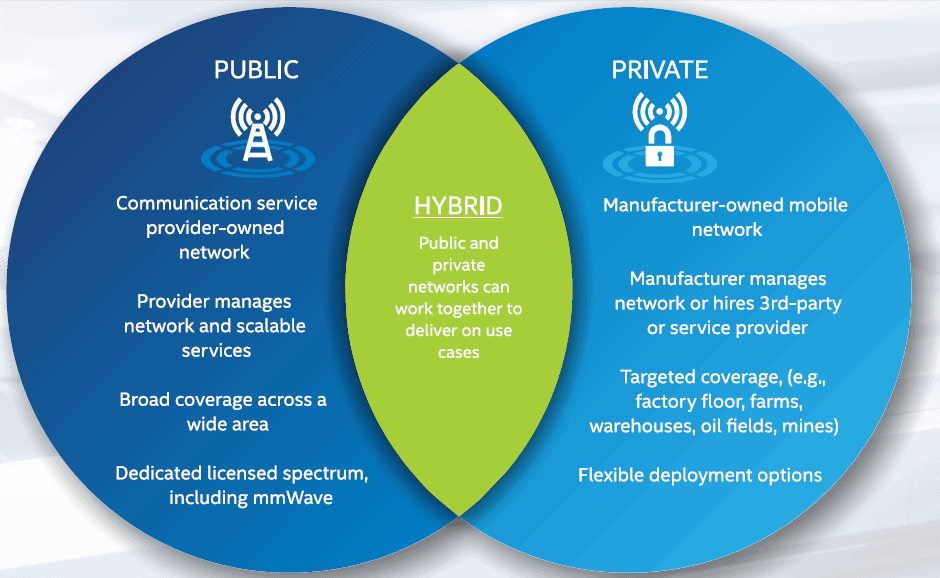

While manufacturers can use 5G public networks, many will opt for 5G private networks that provide highly secure and deterministic connectivity. Private 5G networks advantage of mid-band 5G frequencies to deliver high levels of capacity and operational control to ensure network performance and latency requirements are met. Private 5G networks are the sole property of the owners, giving them exclusive network access, thereby ensuring greater data protection and privacy.

5G and Deterministic Performance

With Release 16, 5G can deliver the necessary network performance with the help of two key technology efforts:

- Time-sensitive networking (TSN) over 5G: This technology provides guaranteed message delivery time using time synchronization and traffic scheduling. Devices can be precisely synchronized over the network, eliminating the need for the signal-based synchronization methods that are common today.

- 5G Ultra-Reliable Low-Latency Communication (URLLC): URLLC optimizes the delivery of data based on different traffic requirements that include low latency and high reliability.

5G and Industry 4.0

The journey to Industry 4.0 requires connecting to all the devices critical to industrial processes. 5G can be key to connect to hard-to-wire devices, and in the future, may become the primary industrial network.

Learn more about 5G and the journey to Industry 4.0 in Intel’s new eBook: 5G Increases Mobility and Flexibility on the Path to Industry 4.0.

Learn more about the technologies that are building the future of industry at the online Intel Industrial Summit 2020, September 23-24th. Register now