Manufacturing’s use of machine learning can help implement better strategies for improved outcomes and optimized solutions.

The manufacturing industry is one of the most complex yet evolving and essential industries. You will notice that there are too many functions involved in a manufacturing unit, and each one is responsible for offering quality and enriched goods.

To maintain the machines, and offer quality products as a result, it is important that the manufacturing industry rely on automation and technology. Apart from relying on custom software solutions, a lot of manufacturing units have started incorporating intelligent machines and technology that can improve their output and make them more efficient.

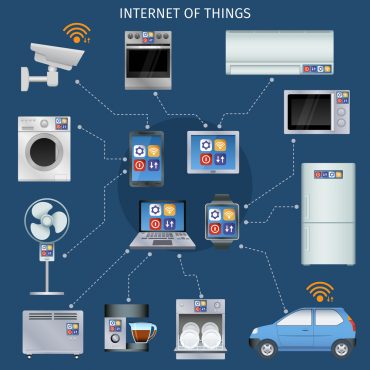

See also: Manufacturing Leads the IoT Pack

Artificial Intelligence is one such technology that can increase the net value of the manufacturing industry from $1.2 trillion to $2 trillion. Apart from offering data-driven solutions, AI can also help with predictive maintenance and preventive measures in the manufacturing industry. Forecasting is another major help that AI-driven systems can offer to this industry.

The machines can learn more about quality and can aim to improve it through better measures and implementing intensive techniques.

Here, we will talk about all the ways in which machine learning, a subset, and a major part of Artificial Intelligence, will revamp the manufacturing industry.

Better and Personalized Manufacturing

Personalization in any segment can offer better value to the industry, and the products therein. It will also help with an increase in user base, thus improving the profits and ROI for your business. When you incorporate machine learning to manufacturing, you are able to understand the end user’s requirements, in this case, retailers and other businesses, better. You know what products they would prefer, which gives you room for innovation and an inherent ability to extend your capabilities. With the right level of data, you will be able to deliver the desired products, which can improve your sales, and in turn, boost your marketing efforts. The production lead-time is also shortened as a result of better and automated processes.

Detect Defects for Superior Quality

The most important consideration for manufacturers is to offer quality products at the output to maximize conversions. It is important that the manufacturer is able to detect the defects in their products early on and discard them, instead of getting all the quantities returned to their unit. With machine learning capabilities, the systems can learn what a defect means for the product and how to identify the defects. Based on this learning, every product is compared, and the defected ones are removed from the batch. This improves defect detection and reduces errors caused due to low quality. In fact, the machines can be used to inspect the quality of the products, which in turn free up your resources and make them available for the core tasks.

Retain Resources, Fight Skill Shortage

Resources can be quite an issue for manufacturers. Getting skilled resources is a need posed by this industry, and it is quite difficult to find that kind of expertise easily. In order to ward off the issues posed by a lack of skilled people within the unit, you can incorporate machine learning. It will help you identify the true potential of the person you are planning to interview or hire and will allow you to hire employees with ease. You won’t need to invest a lot of time into the hiring processes. You would easily find the right person for the job by training the machines to help you.

Predictive Maintenance of Systems

This is the biggest positive that will come out of incorporating machine learning at your manufacturing unit. You will be able to take care of the production line, would be able to identify faults in the system better, and would be able to prevent long-term repairs.

Disruptions in a production line can cause unscheduled downtime and can disrupt your entire schedule. However, with machine learning, you would be able to understand if a system is showing signs of wear and tear. You will be able to send it for repairs immediately. You would be able to resolve issues in a line before it gets out of hand. Mainly, you will be able to get the machines in the clear before it can disrupt your entire manufacturing capabilities.

Securely Scale Operations

The manufacturing sector is immensely dependent on technology to scale their operations and offer seamless growth. It is important that the infrastructure is flexible and secure when scaling the operations and is able to match the requirements fully.

As a result, it has become important to implement the Zero Trust Security Principle, which can ably help with securing the infrastructure and keep up with the safety regulations. With this framework, the manufacturers can ably secure their platform, operating system, the production networks, and even their supply chain. How to implement this framework and the best practices for your company? This question is best answered from past learning, and Machine Learning facilitates the implementation and improves your infrastructure security.

Automating Processes

There are certain batch processes within a manufacturing unit that require efforts from your end. This can reduce the overall time taken to produce a particular batch, and can increase the efforts if you have to use manual resources to implement every aspect. As a result, you ought to automate processes and initiate machine learning frameworks so that the machines know how to respond to certain factors. This will increase the ability of the machine to increase the processes and speed up the production. Eventually, you will be able to produce more and reduce the efforts required for each production process.

Improve Sustainability

The manufacturers are in the process of becoming more sustainable, which requires a complete understanding of their current process and a know-how of how to improve the processes. With a huge line of equipment and processes, it becomes essential for the manufacturers to understand how best to implement a process. AI models can help derive the best process methodology. You will know what kind of issues you are likely to face and how to overcome them. As a result, your model will be thorough and defined. You would be able to run a model of the process before actually implementing it.

Summing Up

Machine Learning is essentially revamping a lot of industries, including manufacturing. It is set to enhance the processes involved and can help implement better strategies for improved outcomes and optimized solutions. You will be able to improve the processability, reduce downtime, and hire better resources with Machine Learning capabilities in your business.