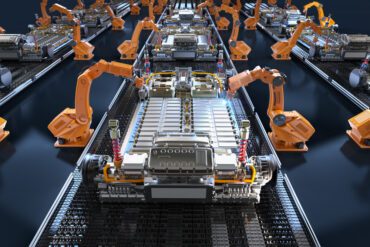

While industrial process change can be a slow process, transformational digital technologies are making inroads in the new smart factory.

Can the smart factory get even smarter? That’s the question on everyone’s minds, as emerging technologies promise to interconnect processes and add intelligence across a broad range of functions.

First, there are still obstacles to be removed. Keith Belton, director of the Manufacturing Policy Initiative at Indiana University, notes that transforming industrial settings can be a slow-moving process, akin to the proverbial turning of a large ship. “Investment cycles in the manufacturing sector are extremely long,” he observed in a recent Industry Week article. “Robust processes and devices will not spring up overnight. Critically, the needed technologies—such as artificial intelligence, or AI—are not yet fully developed.”

However, executives overseeing manufacturing operations clearly understand that digital technologies are in their future. A recent PwC survey also dispels that the notion that “boardroom resistance to investment would get in the way.” It is not just the information flow created by machine connectivity that is so important, “it is the power that these technologies give us to design and innovate great new products that is so significant,” the report’s authors state. “Data from connected machines and people will inform decision-making and reduce costs.”

See also: Industrial IoT gets a smart assist with AI

The PwC survey also shows that a significant share of manufacturing executives expect positive results from their digitization and connectivity initiatives. A total of 70% agree, to varying extents, that data from connected machines and people will inform decision-making and reduce costs.

Nine out of 10 executives also said they are moving forward with smart factory initiatives. “This is an overwhelming endorsement of the increased business efficiency that flows from the adoption of digital technologies,” the report’s authors state. “This allows decision-makers, either humans or machines, to see weaknesses in the system before they become problems, or tweak systems to achieve greater efficiency.”

While there is a constellation of technologies driving the smart factory — such as the Industrial Internet of Things (IIoT), Big Data, and advanced analytics. Information technology (IT) and operations technology — artificial intelligence (AI) is the force driving smart factories. Belton points to “the availability of massive amounts of data, the evolution of machine learning, the advent of cloud computing for network-wide monitoring and optimization and edge computing which provides machine learning for real-time decisions, and the marriage of information technology systems with operations technology systems” as making AI possible,.

Thanks to the proliferation of IoT, AI and IT, predictive analytics is now a key component of smart factories. The authors of a report posted by Lanner recently explored the considerations in building an industrial-scale predictive analytics function:

- Accuracy — as close as possible: “When it comes to predictive analytics, you can’t always be 100% accurate 100% of the time. In some cases, accurate approximations are the best option and when this is the case, the quality of your predictive analytics solution will be the difference between accurate and disparate predictions.”

- Application: “Understanding the application you have in mind for your predictive maintenance system will give you a better idea of which service or solution providers will best suit your needs. If you want a predictive analytics solution to power a preventative maintenance system, inquire with any potential providers about their experience and expertise in this area as well as any examples of how they’ve previously helped clients with preventative maintenance.”

- Integration. “Integration is a huge factor in choosing the right predictive analytics solution for your factory or manufacturing facility. Any future technological additions will likely integrate better if the last addition is prepared for future upgrades and updates. With technological advancement occurring quicker than at any previous point in history, being prepared for future technologies is essential.”