Daikin, the world’s largest heating, ventilation and air conditioning company, is making climate control smarter through real-time IoT and weather forecast adjustments.

Name of Organization: Daikin Industries, Ltd.

Industry: Service

Location: Osaka, Japan

Opportunity or Challenge Encountered: Heating, ventilation and air conditioning (HVAC) is expensive, and a number of technologies have emerged — including building automation systems — over the past three decades to mitigate the costs and energy consumption these systems incur. However, these systems themselves have proven to be costly and complicated. Daikin, the world’s largest supplier of HVAC systems, sought to make their systems more predictive and self-regulating. In addition, the company recognized the disruptive threat coming from large tech firms, which have been offering new home solutions. Adding to the situation was decreasing margins on hardware sales.

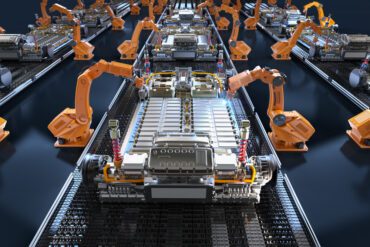

Meeting the Challenge: Over the past several years, Daikin has been adding intelligent IoT capabilities to its various systems, enabling real-time monitoring and control over performance. Daikin’s Intelligent Equipment connects directly to HVAC units to monitor energy consumption at the equipment level for performance measurement, providing access to 150 data points on a rooftop unit or air-cooled chiller in real time. The system provides user interface designed to surface actionable insights on smartphones and computers.

The company applied Intel IoT Gateway configurations to collect information from HVAC sensors and actuators and send it to cloud-based analytics software over cellular networks. The data is then analyzed and integrated with other information such as weather forecasts, the data from which is used to make adjustments in advance of changing conditions. If the temperature is going to rise from 70 degrees one day to 90 the next, the equipment can automatically begin a cooling process overnight to compensate — and save on air conditioning costs the next day.

Through the Intel IoT Gateway, analytics software constantly monitors the equipment’s performance, providing fault detection and predicting maintenance needs and system adjustments. “For example, if a unit has a fan or motor that shows decreasing performance over time, the maintenance crew can inspect and resolve it before the part fails,” the Intel case study relates. In addition, a dashboard provides maintenance notifications and keeps a running history of all service performed on the unit to help ensure it continues to operate at peak performance. In addition, reporting tools give customers in buildings direct access to their power usage and even CO2 emissions.

Benefits From This Initiative: With its real-time IoT capabilities, Daikin is able to provide a range of new services to customers. With the technology, HVAC systems can be monitored and controlled remotely using any mobile device. It moves users from a reactive to a proactive model, in order to quickly adjust ineffective systems and help facility managers maintain equipment before it loses efficiency or impacts occupant comfort. By unlocking the data, Intelligent Equipment also enables managers to make better business decisions. In addition, the company can effectively compete with the looming disruptive threat posed by large technology companies — and even utilities — now offering various intelligent energy management solutions.

(Sources: Daikin, Intel, PARC, a Xerox Company)