The foundation of the industrial metaverse is built on digital twin technology where factories and facilities are represented and open to innovation and experimentation within a virtual world

There’s no end to the chatter about the emerging “metaverse,” which is based on avatars roaming about a virtual landscape, buying virtual things with virtual currencies. However, the metaverse may be seeing its most practical reality from an unexpected quarter: the industrial sector.

The “industrial metaverse” came into full view with the expanded partnership announced between Siemens and NVIDIA intended to “enable the industrial metaverse and increase use of AI-driven digital twin technology.” As a first step in this collaboration, the companies plan to connect Siemens Xcelerator, the open digital business platform, and NVIDIA Omniverse, a platform for 3D design and collaboration. “This will enable an industrial metaverse with physics-based digital models from Siemens and real-time AI from NVIDIA in which companies make decisions faster and with increased confidence,” according to a statement from NVIDIA.

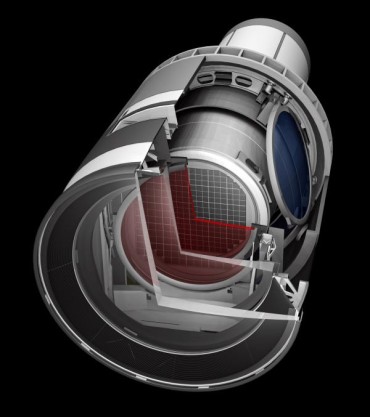

The foundation of such an environment is built on digital twin technology where factories and facilities are represented and open to innovation and experimentation within a virtual world. “The industrial metaverse is basically a digital twin, says Wilhelm Swart, chief operational technologies officer at 4Sight, calling the industrial metaverse “the place where digital dreams will collide with physical reality.” It is here “that digital twin technology will not only be used for fun but also to create giant digital twins of the real world. Digital worlds based on real-time data will allow corporations to have multiple iterations and simulations of themselves.”

See also: 4 Industrial Metaverse Trends: Hyperbole or Revolution?

The “industrial metaverse will accelerate digital transformation,” says R. “Ray” Wang, head of Constellation Research. “The availability of digital twins will offer customers a highly immersive experiences and allow real time decisions in both the physical and digital worlds. Key benefits give customers the ability to create creative environments for rich immersive simulations, and improve productivity for operations.” Additional benefits companies subscribing to the industrial universe include a greater ability to “optimize processes across the product lifecycle, enable access to real-time performance data, and deliver rapid turnaround of industrial IoT solutions,” Wang says.

“Photorealistic, physics-based digital twins embedded in the industrial metaverse offer enormous potential to transform our economies and industries by providing a virtual world where people can interact and collaborate to solve real-world problems. Through this partnership, we will make the industrial metaverse a reality for companies of all sizes,” according to Roland Busch, president and CEO of Siemens AG. “When Siemens Xcelerator is connected to Omniverse, we will enable a real-time, immersive metaverse that connects hardware and software, from the edge to the cloud.”